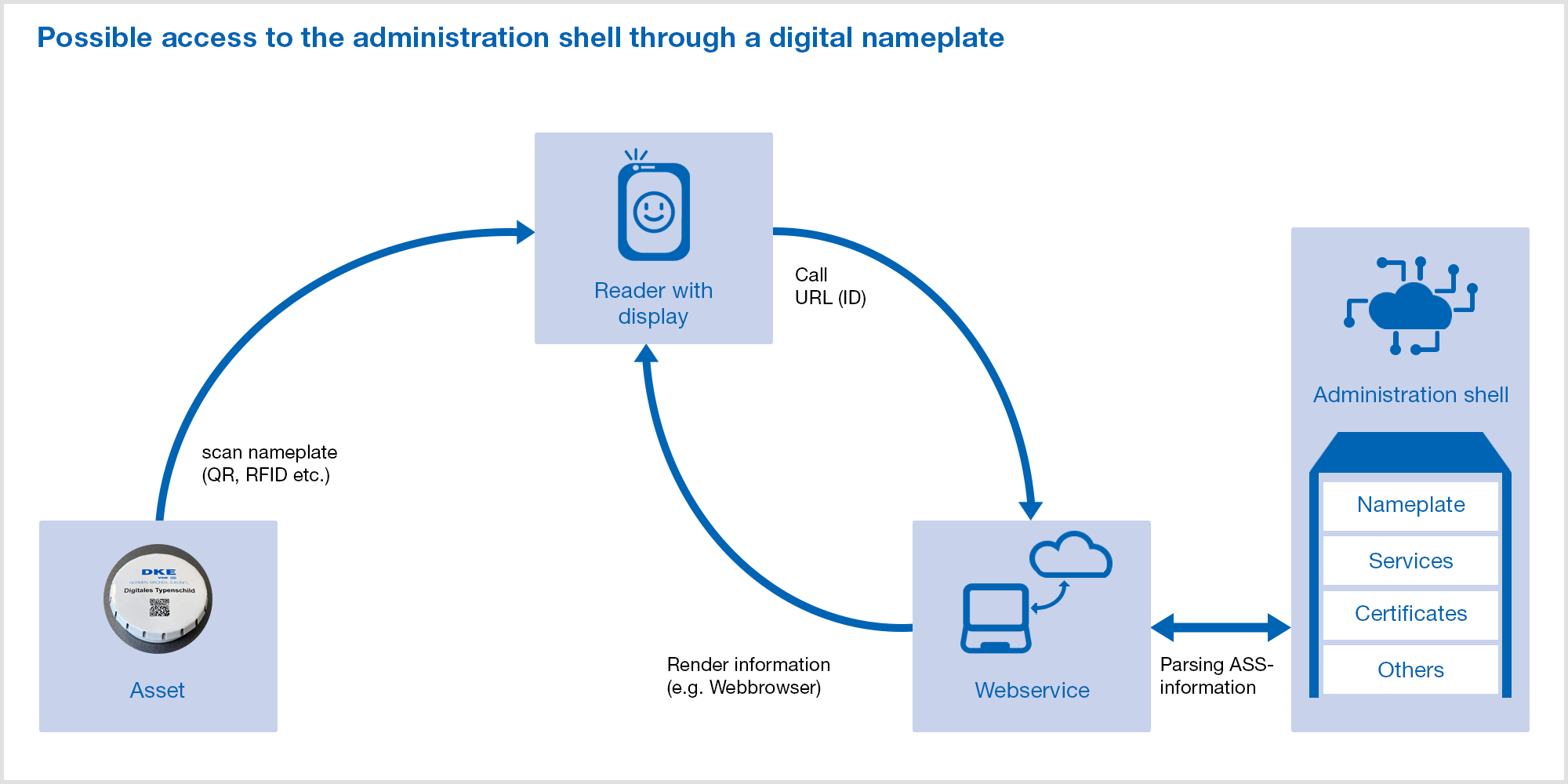

The digital nameplate can be seen as the basis of digitalised value creation processes in terms of the „Industrie 4.0“ concept. With the digital nameplate, information about the product and its life cycle can be clearly assigned and further processed. In addition, the product can be identified in operation and the corresponding information can be used to control industrial processes, e. g. production, maintenance, etc.

With regard to a uniform data concept, the concept of the Asset Administration Shell (AAS) was specified. This enables uniform access to the information assigned to a product (or more generally to an "asset").

The administration shell is organised in different sub-models. Each individual sub-model describes an aspect of the product. Thus, different sub-models come into play for different use cases or life cycles of a product. The digital nameplate forms a central part of the management shell of the respective product in the lowest and most important hierarchy level.

Every product with a digital nameplate and the associated nameplate management shell thus becomes an „Industrie 4.0“ component. Depending on the design of the nameplate, the management shell can be directly connected to the product or stored in external databases.

Further, higher-level sub-models of the management shell contain additional information about the product. For example, there could be a sub-model "identification", where the manufacturer can enter further information on the identity of the product that goes beyond that required in the conventional nameplate (e. g. the product family, the date of manufacture or the batch number). A "document" sub-model is also conceivable, which can be used, for example, to retrieve certificates and certificates of conformity.

In close cooperation with the DKE/K 241 committee, integration into the „Industrie 4.0“ world is being driven forward by the DKE/K 931 committee.

DKE/K 931 with its working groups manages the preparation and support of standardisation projects to define fundamental properties of automation. The focus here is on models, system architectures, structuring of the information inventory and provision of uniform descriptive and linguistic means.